Ukusetshenziswa komugqa weseli ongemuva we-SMT embonini ye-elekthronikhi ye-3C

IGREEN iyinhlangano Kazwelonke Yobuchwepheshe Bezobuchwepheshe ezinikele ku-R&D kanye nokukhiqiza ukuhlanganiswa kwemishini kagesi okuzenzakalelayo kanye nemishini yokupakisha ye-semiconductor kanye nemishini yokuhlola.

Ukusebenzela abaholi bezimboni abanjengo-BYD, Foxconn, TDK, SMIC, Canadian Solar, Midea, kanye namanye amabhizinisi angama-20+ weFortune Global 500. Uzakwethu omethembayo wezixazululo ezithuthukile zokukhiqiza.

I-Surface Mount Technology (SMT) iyinqubo ewumnyombo ekukhiqizeni izinto zikagesi zesimanje, ikakhulukazi embonini ye-3C (ikhompyutha, ukuxhumana, izinto zikagesi zabathengi). Ikhweza izingxenye ezingenamthofu/ezinomthofu omfushane (ama-SMD) ngokuqondile ezindaweni eziphakeme ze-PCB, ivumela ukukhiqizwa okuphezulu kokuminyana, okwenziwe okuncane, okungasindi, okuthembeke kakhulu, nokusebenza kahle kakhulu.Isetshenziswa kanjani imigqa ye-SMT embonini ye-elekthronikhi ye-3C, kanye nemishini ebalulekile kanye nezigaba zenqubo kumugqa weseli we-SMT ongemuva.

□ Imikhiqizo kagesi ye-3C (njengama-smartphones, amaphilisi, amakhompyutha aphathekayo, amawashi ahlakaniphile, ama-headphone, amarutha, njll.) idinga ukwenziwa kancane ngokwedlulele, amaphrofayili amancane, ukusebenza okuphezulu,futhi ngokushesha

Imigqa ye-iteration.SMT isebenza njengendawo yokukhiqiza emaphakathi ebhekana ngqo nalezi zimfuno.

□ Ukuthola I-Extreme Miniaturization kanye ne-Lightweighting:

I-SMT inika amandla ukuhlelwa okuminyene kwezingxenye ezincane (isb, 0201, 01005, noma ama-resistors/capacitor amancane; ama-fine-pitch BGA/CSP chips) kuma-PCB, kwehlisa kakhulu ibhodi lesekhethi

unyawo, ivolumu yedivayisi iyonke, nesisindo—isinikezeli esibalulekile samadivayisi aphathekayo njengama-smartphone.

□ Ukunika amandla I-High-Density Interconnect & Ukusebenza Okuphezulu:

Imikhiqizo yesimanje ye-3C idinga ukusebenza okuyinkimbinkimbi, edinga ama-PCB e-high-density interconnect (HDI) kanye nemizila eyinkimbinkimbi yezendlalelo eziningi. Amakhono okubekwa okunemba kwe-SMT akha i-

isisekelo sokuxhunywa okuthembekile kwezintambo ezixinene kakhulu nama-chips athuthukile (isb, amaphrosesa, amamojula wememori, amayunithi e-RF), okuqinisekisa ukusebenza kahle komkhiqizo.

□ Ukuthuthukisa Ukusebenza Kakuhle Kokukhiqiza Nokunciphisa Izindleko:

Imigqa ye-SMT iletha i-automation ephezulu (ukuphrinta, ukubekwa, ukugeleza kabusha, ukuhlolwa), ukuphuma okushesha kakhulu (isb., amanani okubekwa angaphezu kuka-100,000 CPH), kanye nokungenelela okwenziwa ngesandla okuncane. Lokhu

iqinisekisa ukungaguquguquki okukhethekile, amanani entengo aphezulu, futhi yehlisa ngokuphawulekayo izindleko zeyunithi ngayinye ekukhiqizeni ngobuningi—iqondaniswe ngokuphelele nezidingo zemikhiqizo ye-3C yokushesha ukuya emakethe futhi

amanani okuncintisana.

□ Ukuqinisekisa ukwethembeka nekhwalithi yomkhiqizo:

Izinqubo ezithuthukisiwe ze-SMT—okuhlanganisa ukuphrinta okunembayo, ukubekwa okunembayo okuphezulu, iphrofayela egeleza kabusha elawulwayo, nokuhlola okuqinile okungaphakathi komugqa—isiqinisekiso sokuvumelana kwe-solder kanye

ukwethembeka. Lokhu kunciphisa kakhulu iziphambeko ezinjengamajoyinti abandayo, amabhuloho, nokungaqondani kahle kwengxenye, ukuhlangabezana nezidingo eziqinile zokusebenza kwemikhiqizo ye-3C yemikhiqizo eqinile.

izindawo (isb., ukudlidliza, ukuhamba ngebhayisikili okushisayo).

□ Ukuzivumelanisa nokuphindaphinda komkhiqizo osheshayo:

Ukuhlanganiswa kwezimiso ze-Flexible Manufacturing System (FMS) kwenza imigqa ye-SMT ishintshe ngokushesha phakathi kwamamodeli womkhiqizo, iphendule ngamandla ekuguqukeni okusheshayo.

izidingo zemakethe ye-3C.

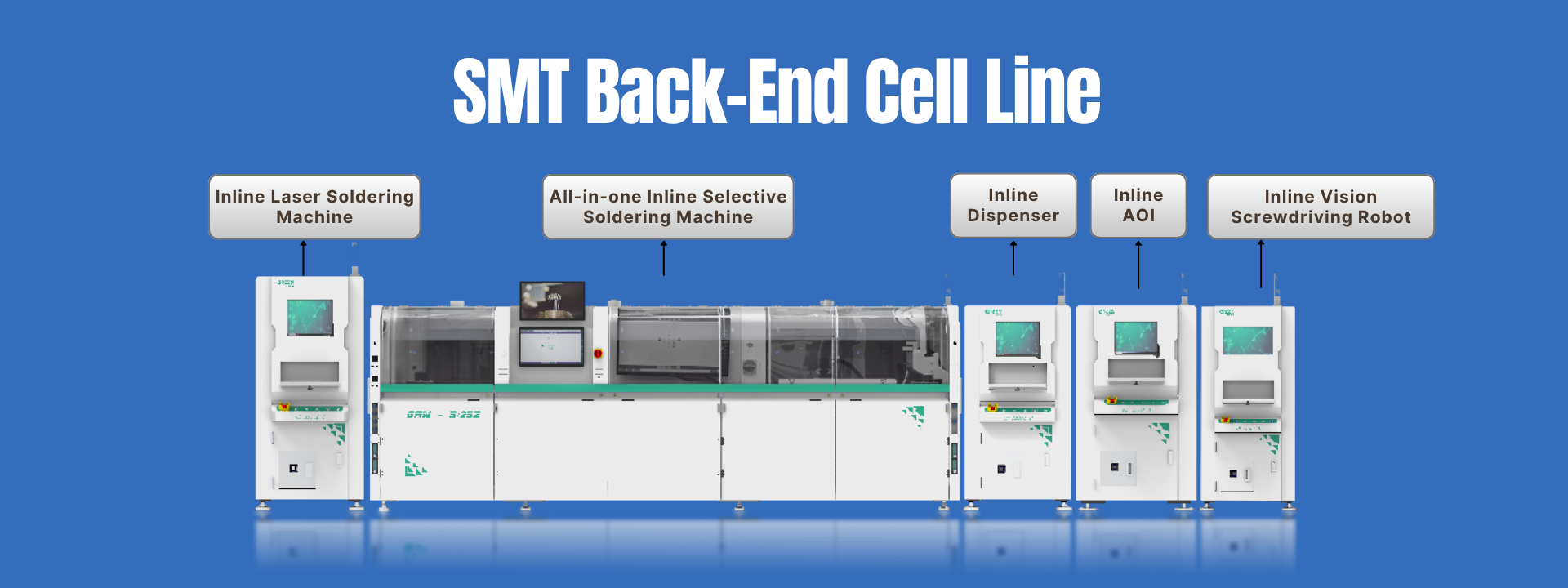

I-Laser Soldering

Inika amandla ukunemba okulawulwa kwezinga lokushisa ukuze kuvinjelwe ukulimala ezingxenyeni ze-thermosensitive. Isebenzisa ukucubungula okungathintana naye okuqeda ingcindezi yemishini, igwema ukususwa kwengxenye noma ukuguqulwa kwe-PCB—okulungiselelwe indawo egobile/engajwayelekile.

I-Wave Soldering ekhethiwe

Ama-PCB anabantu abaningi angena kuhhavini yokugeleza kabusha, lapho iphrofayili yokushisa elawulwa ngokunembile (ukushisa kuqala, ukucwiliswa emanzini, ukugeleza kabusha, ukupholisa) kuncibilikisa ukunamathisela kwe-solder. Lokhu kuvumela ukumanziswa kwamaphedi nemikhondo yengxenye, kwakha amabhondi ensimbi athembekile (amalunga e-solder), okulandelwa ukuqiniswa lapho kupholiswa. Ukuphathwa kwejika lokushisa kubaluleke kakhulu ngekhwalithi yokushisela nokuthembeka kwesikhathi eside.

Ukusabalalisa Okugcwele Okuzenzakalelayo Okusheshayo Okuphezulu Emgqeni

Ama-PCB anabantu abaningi angena kuhhavini yokugeleza kabusha, lapho iphrofayili yokushisa elawulwa ngokunembile (ukushisa kuqala, ukucwiliswa emanzini, ukugeleza kabusha, ukupholisa) kuncibilikisa ukunamathisela kwe-solder. Lokhu kuvumela ukumanziswa kwamaphedi nemikhondo yengxenye, kwakha amabhondi ensimbi athembekile (amalunga e-solder), okulandelwa ukuqiniswa lapho kupholiswa. Ukuphathwa kwejika lokushisa kubaluleke kakhulu ngekhwalithi yokushisela nokuthembeka kwesikhathi eside.

Umshini we-AOI

Ukuhlolwa kwe-Post-Reflow AOI:

Ngemva kokuthengiswa kabusha, amasistimu e-AOI (Automated Optical Inspection) asebenzisa amakhamera anokulungiswa okuphezulu kanye nesofthiwe yokucubungula izithombe ukuze ahlole ngokuzenzakalelayo ikhwalithi ehlangene ye-solder kuma-PCB.

Lokhu kuhlanganisa ukubona amaphutha afana nalawa:I-Solder Defects: I-solder enganele/eqile, amajoyinti abandayo, ibhuloho.Ukukhubazeka Kwengxenye: Ukungaqondani kahle, izingxenye ezingekho, izingxenye ezingalungile, i-polarity ehlehlisiwe, amatshe ethuneni .

Njengendawo yokulawula ikhwalithi ebalulekile emigqeni ye-SMT, i-AOI iqinisekisa ubuqotho bokukhiqiza.

Umshini Wokukrufutha Oqondiswe Emgqeni Oqondiswa Umbono

Ngaphakathi kwemigqa ye-SMT (Surface Mount Technology), lolu hlelo lusebenza njengempahla yangemuva kokuhlanganiswa, luvikela izingxenye ezinkulu noma izakhi zesakhiwo kuma-PCB—njengamasinki okushisa, izixhumi, abakaki bezindlu, njll. Ihlanganisa ukuphakela okuzenzakalelayo kanye nokulawula i-torque ngokunemba, kuyilapho ithola amaphutha okuhlanganisa nezikulufu ezigejiwe, izintambo ezinezintambo ezinemithende.