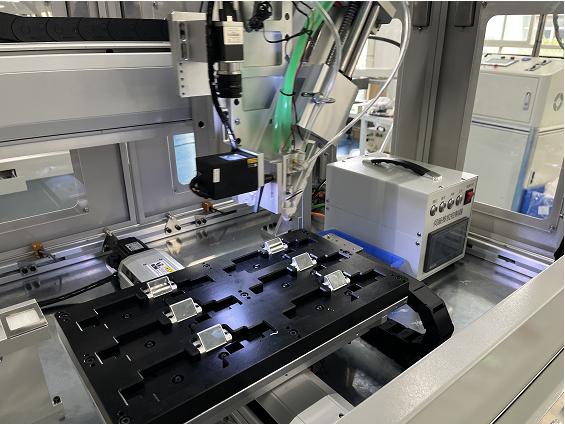

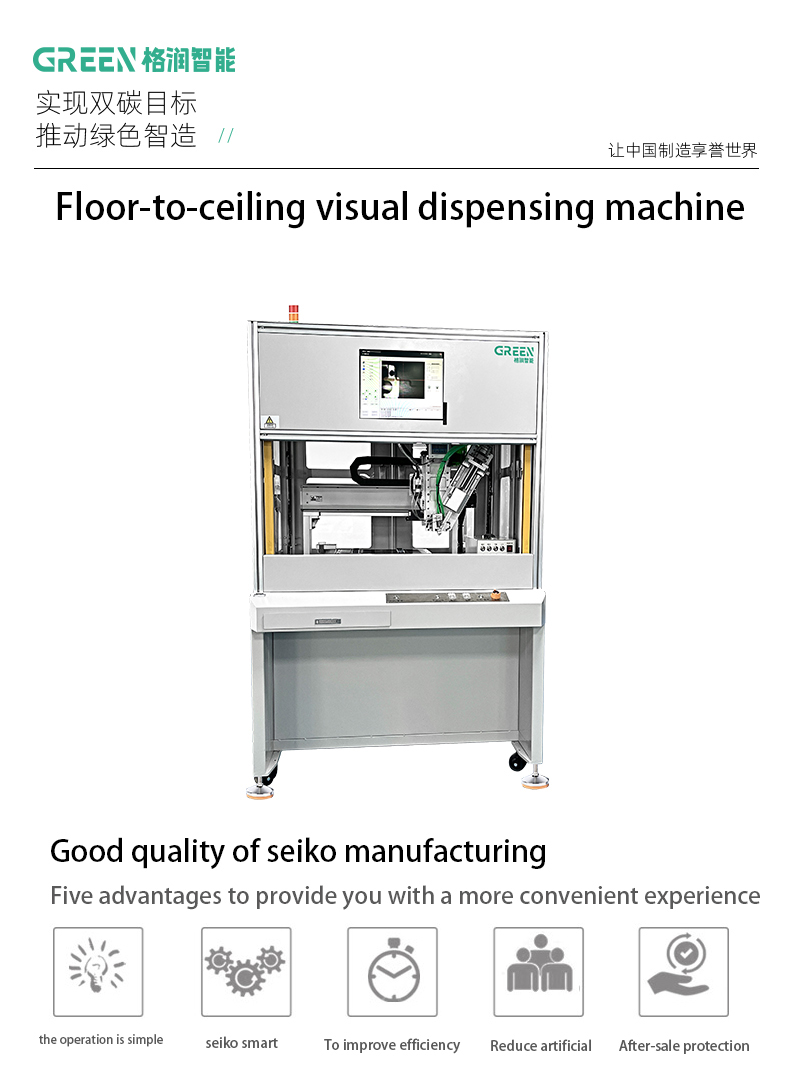

Umshini ohlaza wokubona phansi oluhlaza GR-FD10

Ipharamitha Yedivayisi:

| Imodeli | GR-FD10 |

| I-X-eksisi | 550 mm |

| I-Y-eksisi | 300mm |

| I-Z-eksisi | 100mm |

| Umthwalo we-Z-eksisi | 10Kg |

| Umthwalo we-Y-eksisi | 8Kg |

| Isivinini esihambayo se-XY | 0~800mm/ngesekhondi |

| Z ijubane elihambayo | 0~300mm/ngesekhondi |

| Ubuncane be-diameter ye-spray glue | 0.2mm(kuya ngezakhiwo zeglue) |

| Ukuphindaphinda | ± 0.02 mm/ I-eksisi |

| amagama angukhiye | imishini yokunamathisela |

| Imodi yeDrayivu | I-Stepper motor + ibhande le-synchronous + isitimela esinembayo somhlahlandlela |

| Ikhamera | Inketho ye-1.3 megapixel / 5 megapixel |

| I-Outer demension(L*W*H) | L(1200)*W(950)*H(1910) |

| Okokufaka kwamandla | 220V/50HZ |

| Imodi yokushayela | I-Servo motor + ukunemba isikulufu + ukunemba umhlahlandlela wesitimela |

| Imodi yokubonisa | Gada |

Izici zedivayisi:

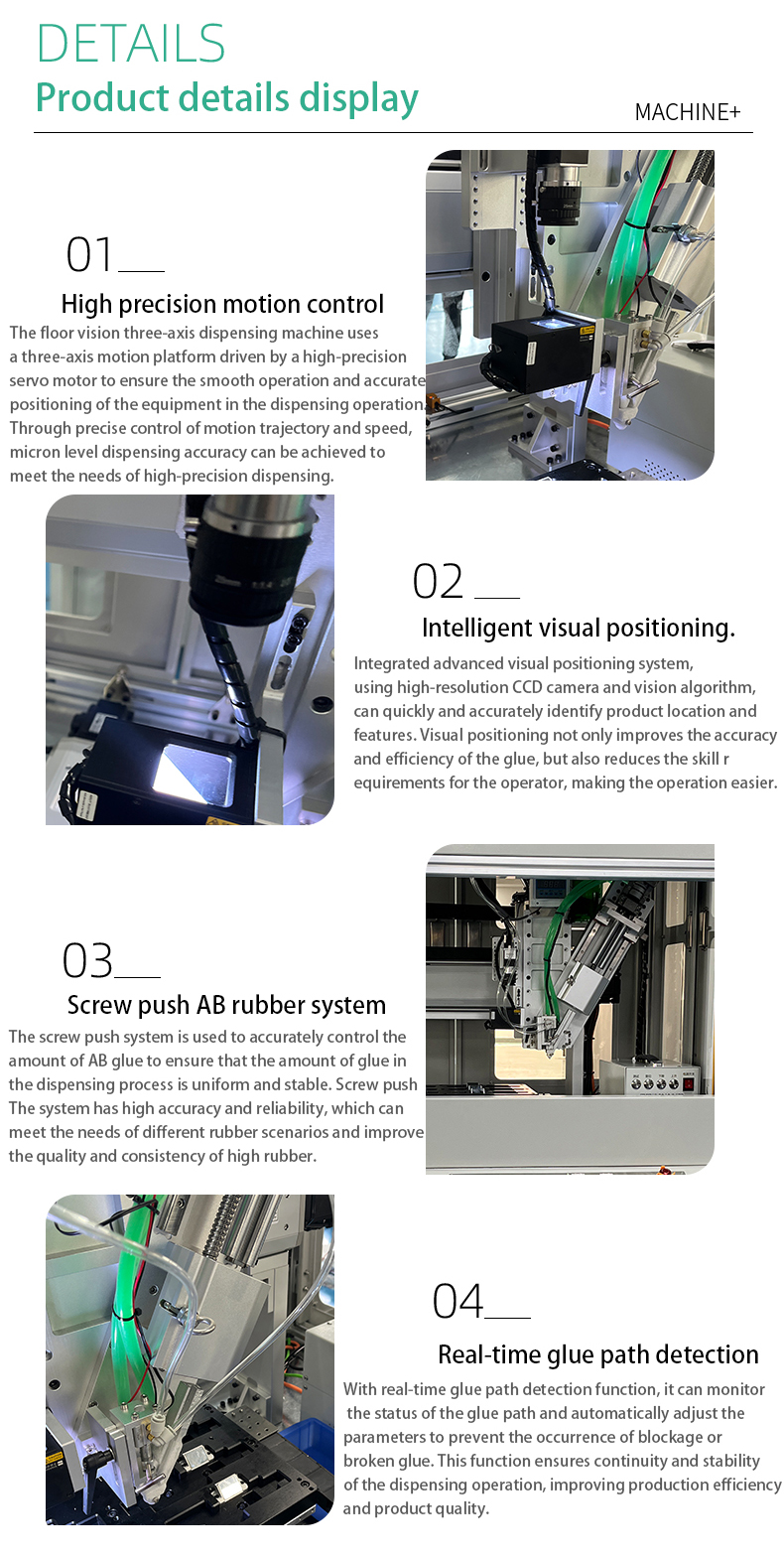

1.Ukulawula ukunyakaza okunembayo okuphezulu Umbono waphansi umshini wokukhipha ama-eksisi amathathu usebenzisa inkundla yokunyakaza ye-axis emithathu eqhutshwa injini ye-servo enembayo ephezulu ukuze kuqinisekiswe ukusebenza kahle nokuma okunembile kwemishini ekusebenzeni kokukhipha. Ngokulawulwa okunembile kwe-motion trajectory kanye nesivinini, ukunemba kokukhishwa kweleveli ye-micron kungafinyelelwa ukuze kuhlangatshezwane nezidingo zokunemba okuphezulu kokusabalalisa.

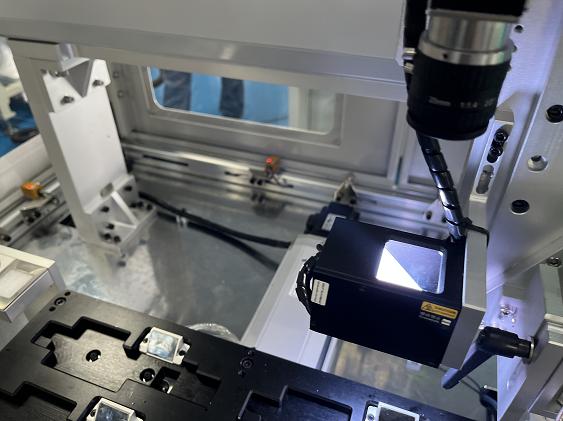

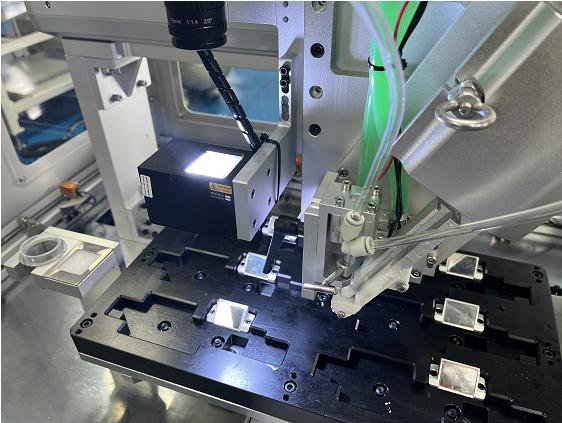

2.Ukuma okubukwayo okuhlakaniphile Lolu cingo luhlanganisa uhlelo oluthuthukisiwe lokuma okubukwayo olusebenzisa amakhamera e-CCD anokulungiswa okuphezulu kanye nezindlela zokubona zokubona ukuze kubonakale ngokushesha futhi ngokunembile izindawo zomkhiqizo nezici. Ukuma okubukwayo akugcini nje ukuthuthukisa ukunemba nokusebenza kahle kweglue, kodwa futhi kunciphisa izidingo zekhono ku-opharetha, okwenza umsebenzi ube lula.

3.Isikulufa sohlelo lwenjoloba lwe-AB Imishini isebenzisa isistimu yokusunduza ngezikulufu ukuze ilawule ngokunembile inani leglue ye-AB ukuze kuqinisekiswe ukuthi inani leglue enqubweni yokukhipha liyafana futhi lizinzile. I-screw push system inokunemba okuphezulu nokuthembeka, okungahlangabezana nezidingo zezigcawu zeglue ezihlukene futhi ithuthukise ikhwalithi nokuvumelana kweglue ephezulu.

4. Umsebenzi wokuskena wekhodi ye-CCD enezinhlangothi ezimbili Ngokuhlanganisa umsebenzi wokuskena wekhodi we-CCD enezinhlangothi ezimbili, idivayisi ingakwazi ukuhlonza ngokushesha ulwazi lwekhodi enezinhlangothi ezimbili emkhiqizweni ukuze kuzuzwe ukulandeleka komkhiqizo nokuphathwa kweqoqo. Leli khono likhulisa ukucaca nokulawula inqubo yokukhiqiza, okunomthelela ekuthuthukisweni kwekhwalithi yomkhiqizo kanye nokwaneliseka kwamakhasimende.

I-5.Ukutholwa kwendlela yenjoloba yesikhathi sangempela Imishini inomsebenzi wokuthola indlela yeglue ngesikhathi sangempela, engakwazi ukuqapha isimo sendlela yeglue futhi ilungise ngokuzenzakalelayo imingcele ukuvimbela ukuvela kokuvinjelwa noma ukuphulwa kweglue. Lo msebenzi uqinisekisa ukuqhubeka nokuzinza komsebenzi wokusabalalisa, ukuthuthukisa ukusebenza kahle kokukhiqiza kanye nekhwalithi yomkhiqizo.

6. Isixhumi esibonakalayo sokusebenza komuntu Idivayisi ifakwe isixhumi esibonakalayo sokusebenza esinembile nesinobungane, esilungele opharetha ukuthi asethe imingcele futhi aqaphe inqubo yokukhipha. Idizayini yesixhumi esibonakalayo ilula futhi icacile, ukusebenza kulula, futhi ubunzima bokusebenza kanye nengozi yokungasebenzi kahle kuyancipha.

7.Ukusebenza okuzinzile nokunokwethenjelwa Umshini wokukhipha ama-axis amathathu obekwe phansi phansi wenziwa ngezinto ezisezingeni eliphezulu kanye nobuchwepheshe bomshini wokunemba, ngokuzinza okuhle nokuthembeka. Izinto zokusebenza zingasebenza ngokuqhubekayo isikhathi eside futhi zigcine ukusebenza kokusabalalisa okuzinzile ukuze kuhlangatshezwane nezidingo zokukhiqiza okukhulu.