Plastic Laser Welding Machine LAESJ220

Imininingwane

| I gama le-brand | OKULUHLAZA |

| Imodeli | I-LAESJ220 |

| Igama Lomkhiqizo | I-Laser Soldering Machine |

| I-Laser Wavelength | 1064 mm |

| Laser Amandla | 200W |

| Ibanga likagesi eliguquguqukayo | 0.2-2mm |

| Imodi ye-Dive | I-AC380V 40A 50HZ |

| Uhlobo | Umshini Wokugcwalisa |

| Amandla Alinganiselwe | 4KW |

| Ubuningi Bamanje | 10A |

| Isisindo (KG) | 200 KG |

| Ukuthwala umthwalo | 150KG |

| Amaphuzu Okuthengisa Abalulekile | Okuzenzakalelayo |

| Le yindawo ka Origin | China |

| Iwaranti yezingxenye eziyinhloko | 1 Unyaka |

| Iwaranti | 1 Unyaka |

| Ukuhlola okuphumayo kwevidiyo | Kuhlinzekiwe |

| Umbiko Wokuhlolwa Kwemishini | Kuhlinzekiwe |

| Indawo ye-Showroom | Lutho |

| Uhlobo Lokumaketha | Umkhiqizo Ojwayelekile |

| Isimo | Okusha |

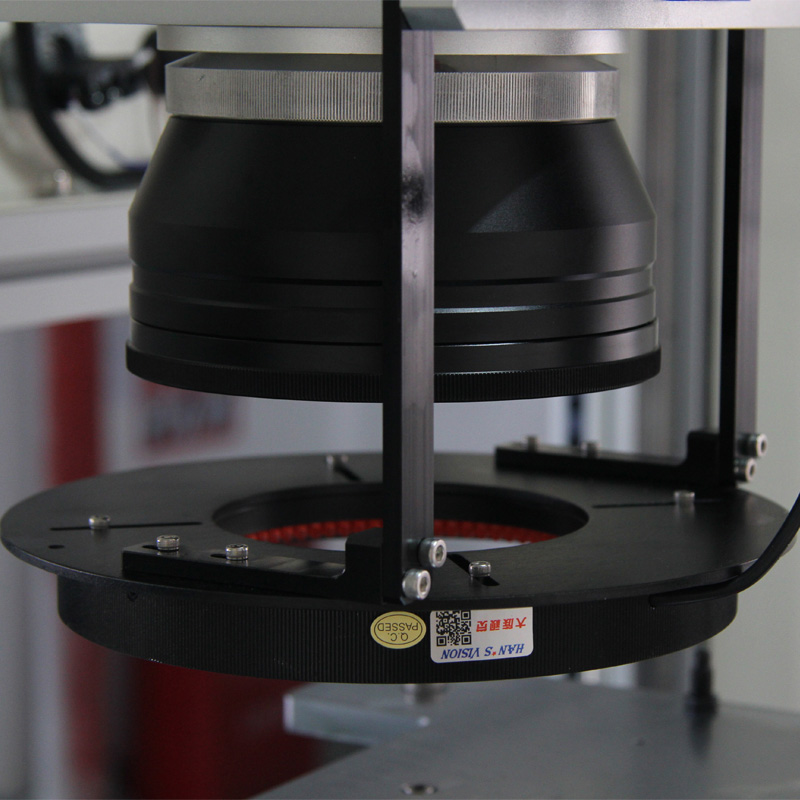

| Izingxenye Eziyinhloko | Ikhompyutha yezimboni, i-Stpping motor, ibhande le-synchronous, i-Precision Guide Rail, Ikhamera |

| Izimboni Ezisebenzayo | Izitolo Zokulungisa Imishini, Imboni Yokukhiqiza, Okunye, Imboni Yezokuxhumana, 3C Consumer Electronics Industry, Imboni Yezimoto, Imboni Yamandla Entsha, Imboni Ye-LED, Imboni Yezogesi |

Isici

Irobhothi elisha le-desktop ethengiswayo ye-Industry 4.0 ne-IoT.

I-Green Intelligent Series ithuthukise umsebenzi wayo wenethiwekhi kanye nokunyakaza kwamarobhothi.

Izinhlobo ezintathu, ngokusho kosayizi we-PCB. Lezi ziyasebenza futhi zenzelwe i-laser soldering.

Ingakwazi ukuxhuma nenethiwekhi, engakwazi ukubona ngeso lengqondo inqubo ngayinye yokuhlanganisa kanye nomphumela.

Izimbazo ezimbili ezengeziwe zisiza ama-engeli okungena noma ukuzungezisa i-PCB, okwenza ingxenye enzima yokusoda yenzeke kusukela manje kuqhubeke.

Imisebenzi yenethiwekhi ethuthukisiwe yemboni 4.0

Ukusekela ukuthunyelwa kwedatha kanye nokulawulwa kwenqubo yangaphandle nge-LAN noma imbobo ye-COM.

Isofthiwe yokuqapha ekhethekile ingaqapha ukude isimo sokusebenza.

Ukuqapha kwesikhathi sangempela njenge-temp. igrafu, isimo sokusebenza, amaphutha angavimbela imikhiqizo enesici.

Amarobhothi ayalawuleka ngokuxhuma ku-PLC kanye nemiyalo yokulawula. Ubudlelwano phakathi kwenethiwekhi yefekthri nochungechunge lwe-DF.

I-PLC, i-LAN namahabhu ahlinzekwa ngamakhasimende.

I-3D soldering ne-MID (idivayisi yokuxhuma ebunjiwe)

Izimbazo ezimbili ezengeziwe zivumela ukusoda kwe-PCB okuyinkimbinkimbi futhi okuguquguqukayo.Izimbazo ezimbili zingengezwa endaweni yokusebenza.Izimbazo ezimbili zingangezwa ngokukhetha, kufika kweziyisithupha izimbazo. Amadivayisi angaphandle alawuleka ngokuphelele ngokusebenza kwenqwaba yerobhothi.Ukunyakaza okuhlukahlukene njengokuzungezisa ingxenye, ukuhlehla kwe-PCB, ama-engeli ekhanda, ukuzungezisa izingxenye eziyisilinda, ukucisha ikhebula, njll. Ukonga isikhala nokusetha kalula.

I-heater entsha ithuthukisa kakhulu ukukhiqiza

Isilinganiso sokushisa esinembe kakhulu sifinyelelwe ngokubeka inzwa yokushisa ekugcineni kwethiphu.

Izinga lokushisa elisheshayo. ukululama kufeza ukusebenza kahle okuphezulu.

I-heater kanye nethiphu kuyahlukaniswa futhi kungashintshwa ngakunye.

Umsebenzi wokumisa onembile uvimbela ukwenza amaphutha okufaka ithiphu yokunamathisela kanye nesiqondiso sayo

Kulula ukushintsha ukukhethwa kohlelo ebhokisini lokushintsha

Iswishi ephakathi ingashintsha ngokushesha izinhlelo.

Isikhethi sokuthinta okukodwa ebhokisini lokushintsha

Izinhlelo ezingafanele ziyakhetheka futhi zenziwe (2ch)

Okwezimboni 4.0. Ukuphathwa kwedatha yenqubo ngayinye yokuhlanganisa

Ngokuxhuma isofthiwe yokuqapha ye-DF, izinqubo ezihlukahlukene zokuhlanganisa ezifana nezinga lokushisa, ukuqaliswa kohlelo nokunye kuyabonwa futhi kuguqulelwe kudatha yezinombolo.

Isibonelo, ukubheka izinga lokushisa ngesikhathi sokuthengisa, uma ukuguquka kwezinga lokushisa okungavamile noma ukwenziwa kohlelo kwenzeka, isistimu yokuqapha ithwebula ukungahambi kahle kwayo futhi ingazisa amaphutha.

Ngaphezu kwalokho, ukuxhuma kwi-Inthanethi / intranet, uhlelo lungazisa iphutha futhi lungathumela uqaphile ku-imeyili ebhalisiwe. Ukubuka okunjalo kwesikhathi sangempela kukuvumela ukuthi uphendule ngokushesha kumaphutha okusebenza kanye nokukhubazeka.

Noma iyiphi idatha ingathunyelwa ngefomethi ye-CSV. Idatha yelogi yokusebenza ehlukahlukene evela kunqubo ngayinye ingaba usizo ekuphenyeni nasekuhloleni ukuze kuthuthukiswe ukukhiqiza okuqhubekayo.

Enye isoftware ethuthukisiwe yokuphatha i-soldering “Soldering Manager” (inguqulo ekhokhelwe) isiyatholakala.