Isicelo ku Semiconductor Industry

IGREEN iyinhlangano Kazwelonke Yobuchwepheshe Bezobuchwepheshe ezinikele ku-R&D kanye nokukhiqiza ukuhlanganiswa kwemishini kagesi okuzenzakalelayo kanye nemishini yokupakisha ye-semiconductor kanye nemishini yokuhlola. Ukusebenzela abaholi bezimboni abanjengo-BYD, Foxconn, TDK, SMIC, Canadian Solar, Midea, kanye namanye amabhizinisi angama-20+ weFortune Global 500. Uzakwethu omethembayo wezixazululo ezithuthukile zokukhiqiza.

Imishini yokubopha inika amandla ama-micro-interconnects ngamadayimitha ocingo, iqinisekisa ubuqotho besignali; i-formic acid vacuum soldering yakha amajoyini athembekile ngaphansi kokuqukethwe kwe-oxygen <10ppm, ukuvimbela ukwehluleka kwe-oxidation emaphaketheni aphezulu; I-AOI ivimba ukukhubazeka kwezinga le-micron. Le synergy iqinisekisa> 99.95% isivuno sokupakisha esithuthukisiwe, sihlangabezana nezidingo ezidlulele zokuhlola zama-chips we-5G/AI.

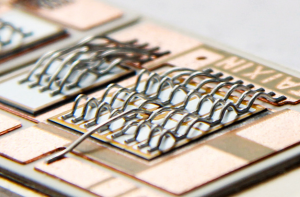

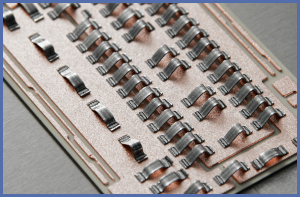

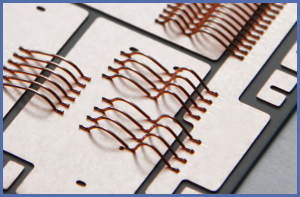

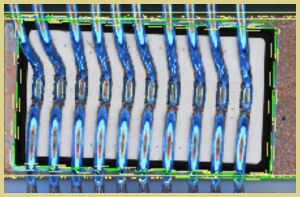

I-Ultrasonic Wire Bonder

Iyakwazi ukuhlanganisa i-aluminium engu-100 μm–500 μm, intambo yethusi engu-200 μm–500 μm, amaribhoni e-aluminium afika ku-2000 μm ububanzi no-300 μm obukhulu, kanye namaribhoni ethusi.

Ibanga lokuhamba: 300 mm × 300 mm, 300 mm × 800 mm (okungezifiso), nokuphindaphinda < ±3 μm

Ibanga lokuhamba: 100 mm × 100 mm, ngokuphindaphinda < ±3 μm

Iyini i-Wire Bonding Technology?

I-wire bonding iyindlela yokuxhumana ye-microelectronic esetshenziselwa ukuxhuma amadivaysi e-semiconductor emaphaketheni awo noma kuma-substrates. Njengobunye bobuchwepheshe obubaluleke kakhulu embonini ye-semiconductor, yenza ukuxhumana kwe-chip namasekethe angaphandle kumadivayisi kagesi.

I-Bonding Wire Materials

1. I-Aluminium (Al)

I-Superior conductivity kagesi iqhathaniswa negolide, eyongayo

2. Ithusi (Cu)

25% ephakeme kagesi/i-thermal conductivity kune-Au

3. Igolide (Au)

I-conductivity ekahle, ukumelana nokugqwala, nokuthembeka kokubopha

4. Isiliva (Ag)

I-conductivity ephezulu kakhulu phakathi kwezinsimbi

I-Aluminium Wire

I-Aluminium Ribbon

Intambo yethusi

Iribhoni Lethusi

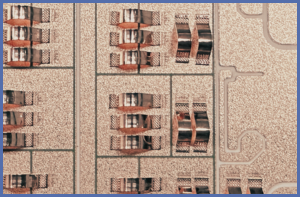

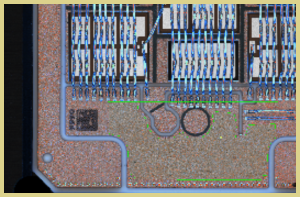

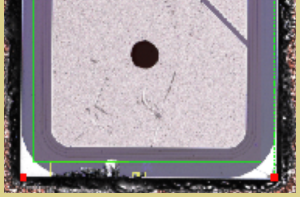

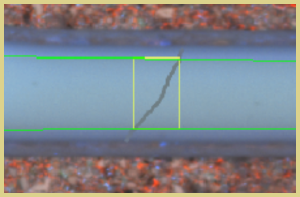

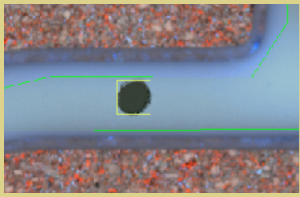

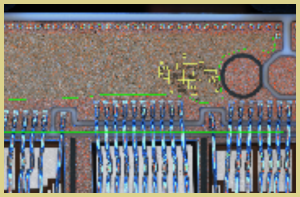

I-Semiconductor Die Bonding & Wire Bonding AOI

Isebenzisa ikhamera yezimboni engu-25-megapixel ukuze ithole ukunamathiselwe kwentambo kanye nokulimala kokubopha izintambo emikhiqizweni efana nama-IC, ama-IGBT, ama-MOSFET, namafreyimu aholayo, kufinyelele izinga lokutholwa kokukhubazeka elingaphezu kuka-99.9%.

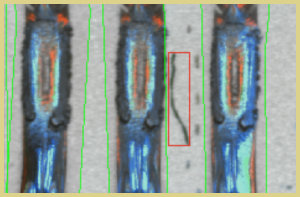

Amacala Okuhlola

Iyakwazi ukuhlola ukuphakama kwe-chip nokucaba, i-chip offset, ukutsheka, nokuchopha; Ibhola le-solder elinganamatheli kanye ne-solder joint detachment; izintambo ezingalungile ezihlanganisa ukuphakama kweluphu okweqile noma okunganele, ukuwa kweluphu, izintambo eziphukile, izintambo ezingekho, ukuthintana kwezintambo, ukugoba izintambo, ukuwela iluphu, nobude obuningi bomsila; ukunamathela okunganele; kanye ne-metal splatter.

Ibhola leSolder/ Izinsalela

I-Chip Scratch

Ukubekwa kwe-chip, ubukhulu, i-Tilt Meas

Ukungcoliswa kwe-Chip/Izinto Zangaphandle

I-Chip Chipping

I-Ceramic Trench Cracks

Ukungcola Kwe-Ceramic Trench

I-AMB Oxidation

I-Ovini Yokugeleza Kabusha kwe-Formic Acid

1. Izinga lokushisa eliphezulu ≥ 450°C,izinga elincane levacuum <5 Pa

2. Isekela indawo yenqubo ye-formic acid ne-nitrogen

3. Izinga elingenalutho lephoyinti elilodwa ≦ 1%,izinga elingenalutho lilonke ≦ 2%

4. Ukupholisa amanzi + ukupholisa i-nitrogen, okufakwe isistimu yokupholisa amanzi kanye nokupholisa okuthintana naye

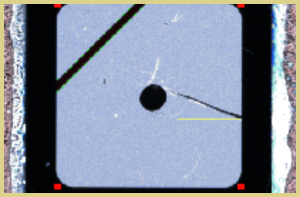

I-IGBT Power Semiconductor

Amazinga e-voiding eqile ekufakweni kwe-IGBT angabangela ukuhluleka kokusabela kweketango okuhlanganisa ukubaleka okushisayo, ukuqhekeka komshini, nokonakaliswa kokusebenza kukagesi. Ukunciphisa izilinganiso ezingenalutho ukuya ku-≤1% kuthuthukisa kakhulu ukuthembeka kwedivayisi nokusebenza kahle kwamandla.

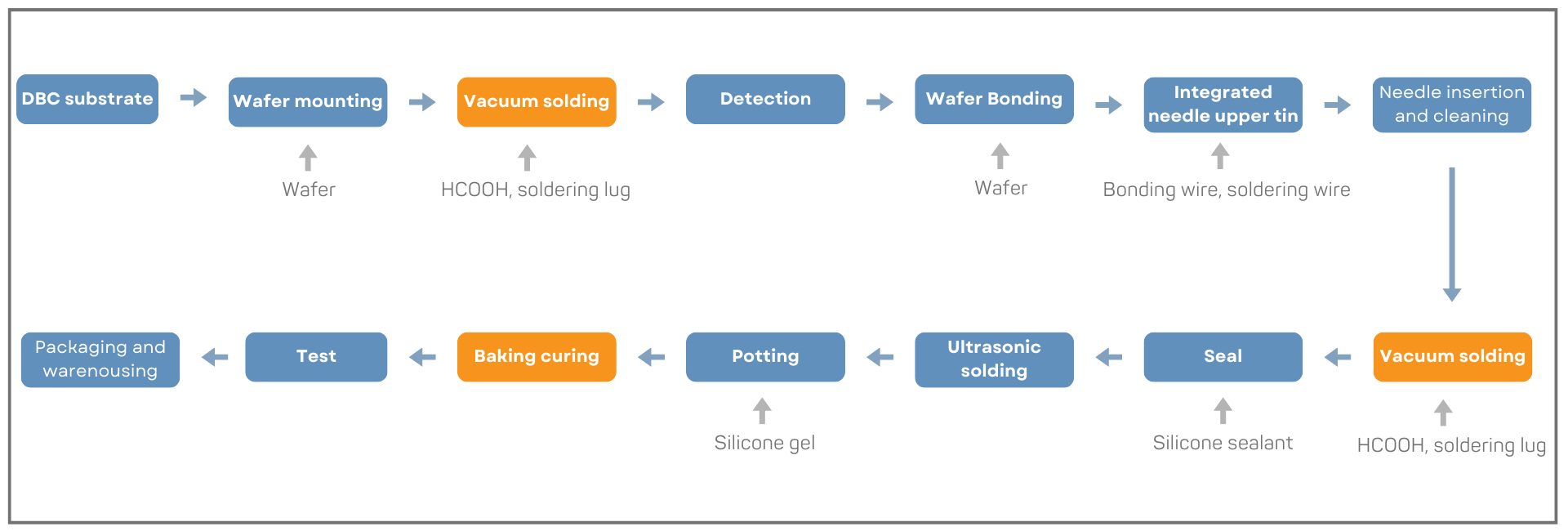

I-flowchart yenqubo yokukhiqiza ye-IGBT